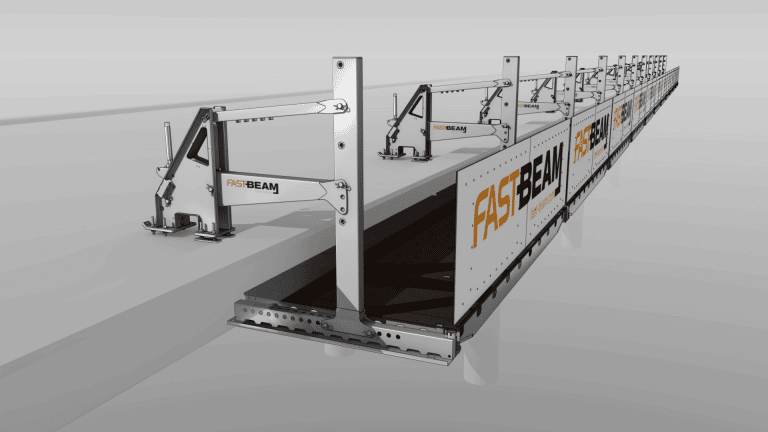

Fast Beam is suited for any kind of deck, both concrete and steel. The length of the deck is not a factor.

The floating scaffolding system can be installed anywhere and everywhere: bridges, jetties, docks, dams, parking houses, canals, viaducts, flyovers, and more.

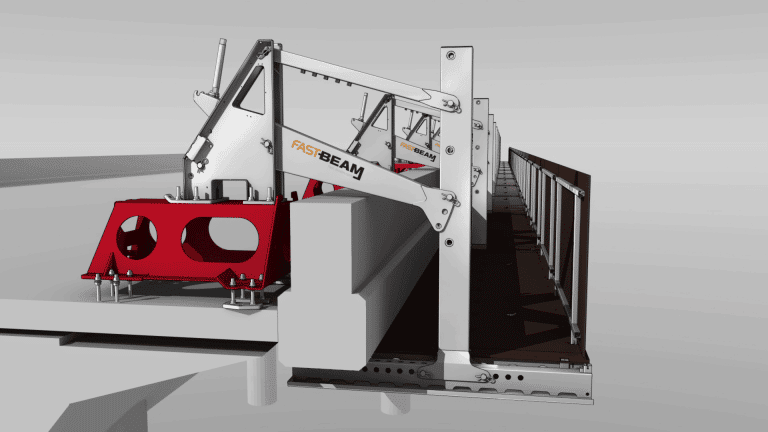

Fast Beam is for parapet reparations, formwork, casting & rebar work.

The Fast Beam scaffolding system also suits sites and projects that require hydrodemolition or grounding, ecologically sensitive sites as well as work on curved or damaged decks.

Fast Beam is easy to install, operate and dismantle. The system is fixed to the deck, meaning that your projects become uniform, and they increase in speed and efficiency.

Quick installation and dismantling on any deck.

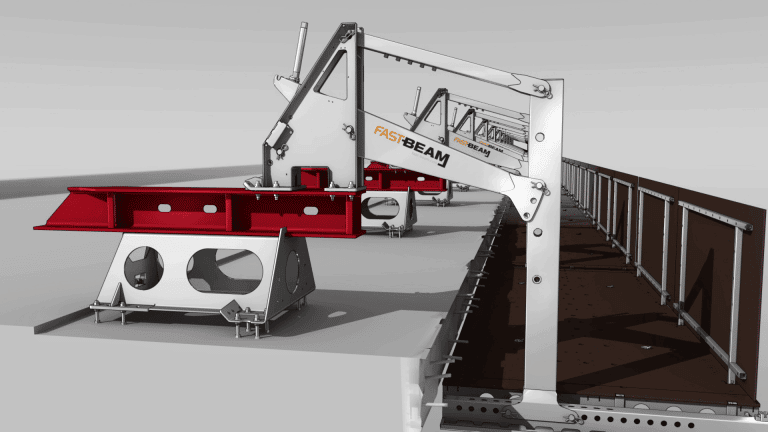

Easy to use, learn, teach and deploy in your organization.

Safety and ergonomics are core in the process.

Small carbon footprint.

Fast Beam is compact, and it is easy to store, transport and use. When fixed, the system usually needs less than one meter of room on the deck. With Fast Beam traffic disruptions are kept to a bare minimum.

The system’s flexibility allows for installation also on curved decks. As Fast Beam is a floating platform system, any traffic below the deck can flow undisturbed.

The adjustable platforms provides the ergonomic work setting for your crews. Keep your crews safe, even in the most physically demanding tasks.

Fast Beam provides the necessary training and materials for you to succeed. The system itself as well as the installation, use and removal is easy to learn – and teach.

As your crews learn how to properly use Fast Beam, their efficiency will be increased. Experienced installation crews achieve up to 100 meters of installed scaffolding per workday.

Awarded for innovation and good practice for the first Highways England major project to use the Fast Beam on a scheme.

Deck length 68 m

Deck length 27 m